The Advantages of 3D Printing

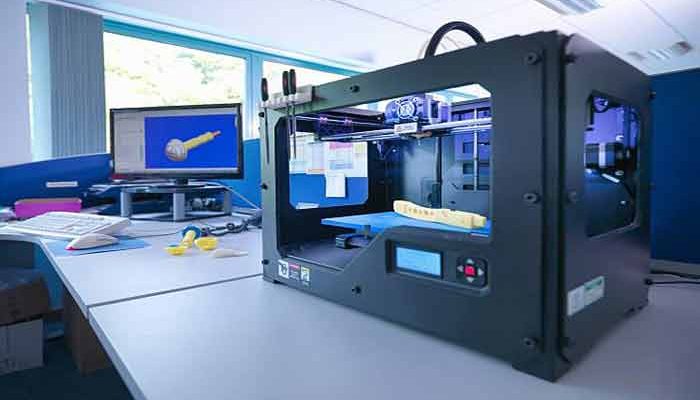

In this fast-paced world, 3D printing is essential for fast and efficient production of parts. Unlike traditional methods, 3D printing can convert a complex design from a CAD model into a physical object in just a few hours. This helps designers test their concepts and designs in a short time, while traditional methods take weeks or months to go from design to production. Despite its many benefits, 3D printing is still new to many companies.

Customize Parts in One Build

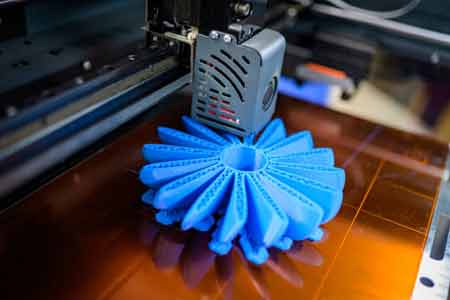

One of the advantages of 3D printing is its ease of customization. The ability to create different configurations for the same part in just one build is a significant advantage. This makes it an ideal choice for one-off productions and for building single parts in a single step. Due to its ease of use and affordability, 3D printing has a wide range of applications, including medical and dental industries. With its flexibility and customizable features, 3D printing can even be used for customized sporting gear, like helmets and sports braces.

3D Printing Offers Competitive Edge

The process of 3D printing is also easy and fast. Using it to produce prototypes and models is much more cost-effective than using traditional manufacturing methods. Compared to conventional methods, 3D printing allows for step-by-step assembly of parts, boosting the design of an existing product, and allowing for modifications. All of these benefits are vital in creating high-quality products. If you are looking for a competitive edge, 3D printing can give you that edge. So, don’t wait. Get started with 3D technology today. You’ll be pleasantly surprised at the possibilities that this technology can bring to you.

Reduces Cost of Production

Using 3D printers can reduce your costs of production. Since 3D printers can print everything from small components to entire products, you can design your product in one country and have it manufactured in another. Then, just send the design files to the other country and have it produced in the same way. This can cut down on costly road and air travel. By minimizing transportation costs, 3D printing can save you money and energy.

Aside from saving money, 3D printing can also help businesses save on shipping. With best 3d printer, your production process can be more cost-efficient than ever before. Your product will be delivered sooner. A few years from now, you’ll be able to reduce the amount of waste you throw away. Aside from reducing the cost of shipping, you’ll have more time to focus on marketing and sales.

Makes Manufacturing More Flexible

Unlike conventional manufacturing methods, 3D printing allows you to make the final product from scratch. As you design, you’ll be able to modify the shape and size of the product until you find a perfect fit. In addition to reducing costs, 3D printing also allows you to test the materials before manufacturing. The process is more efficient than traditional manufacturing methods and does not require forecasting of demand. It is more flexible. Now learn more about how dose a 3D scanner cost.

Allows You to Make Multiple Copies

You can quickly create spare parts. Your prototypes can be more efficient and accurate if they have no defects. You can also produce multiple copies of the same product. That way, you can test out different designs and decide which ones will work better. It’s not only fast and affordable, it also allows you to use 3D printers in large-scale production. Moreover, it reduces costs by as much as 50 percent.

Conclusion

Many industries have long and expensive production processes. First, you need a CAD model, which then requires you to make a prototype. Then you need to make adjustments to the final product. All of these steps can be done in one step with 3D printing. Then, it’s time for the final product. And finally, you can control the final product. In this way, 3D printing is the future.